3-point bending test|3 point bending test calculator : traders Elastic modulus in bending (i.e., flexural modulus), stress-strain behavior, and failure limits in bending all can be obtained using the simple sample geometry of a 3-point bend test. ASTM D790 or ISO 178 covers flexural properties for .

By Robbie Peterson August 17, 2023. • Bodhi Soleil Reed Somerhalder is a three-year-old celebrity child born in Los Angeles, California USA. • She is a millionaire, thanks to the wealth of her famous parents, Ian .

{plog:ftitle_list}

Resultado da Mahjong. Jogue Kris Mahjong gratuitamente no CrazyGames. É um dos nossos melhores jogos de Puzzle!

The three-point flexural test measures the flexural properties of materials by applying a load at the midpoint of a supported beam, providing insights into flexural strength, .The three point bend test (Figure 1) is a classical experiment in mechanics, used to measure the Young’s modulus of a material in the shape of a beam. The beam, of length L, rests on two .

The three-point bending technique is a material testing method which evaluates modulus of elasticity in bending, flexural stress and flexural strain when the material sample is set up as .The 3-point bend test to ISO 178 is used for the determination of flexural properties of thermosets and thermoplastics. The most common results obtained with this test are the .

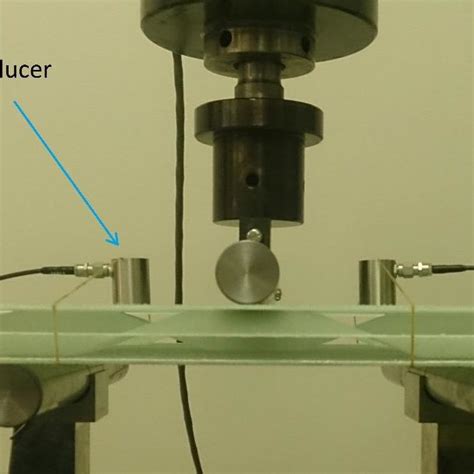

The specimen used for the three-point bending test is a beam similar to the one sketched in Figure 3. The use of a span much larger than the cross-sectional height is intended to mitigate .Elastic modulus in bending (i.e., flexural modulus), stress-strain behavior, and failure limits in bending all can be obtained using the simple sample geometry of a 3-point bend test. ASTM D790 or ISO 178 covers flexural properties for .This test is performed on a universal testing machine (tensile testing machine or tensile tester) with a 3 point or 4 point bend fixture. The key analysis when performing bend testing are: Flexural Modulus – This measures the slope of a .A three-point bend test applies force at the midpoint of a rectangular specimen, which is freely supported at either end. The applied force is measured by a load cell, and the resulting deflection is measured by either the system’s crosshead displacement (with results corrected for system compliance) or by a direct strain measurement device .

Place the test bar on the 3 point bend fixture and begin the test and end after bending to 5% deflection or until the sample breaks. Tips: Testing speed: The speed of the test is very slow and variable depending on the support span .

The three-point bend test is standardized under ASTM D790 and ISO 178, ensuring consistency and reliability in the results. A standard test method in material testing provides a uniform framework for conducting tests, enabling the comparison of results across different studies and applications. These standards outline specific procedures for .

3.2 Fixtures, specimen positioning and CMOD installation Put the machine in standby mode via rotating the switch denoted by #4 (in Figure 1) to its leftmost position. With the help of the present supervisor, change the fixtures of the machine (#5 in Figure 1) and install the ones suitable for the three-point bending test, as demonstrated in .A bend test can fail due to the presence of defects in the material, lack of ductility, or the material’s inability to withstand the applied bending stress. What does the 3 point bend test determine? The three-point bend test determines the flexural strength or the ability of a material to resist deformation under load. 1.1 These test methods are used to determine the flexural properties of unreinforced and reinforced plastics, including high modulus composites and electrical insulating materials utilizing a three-point loading system to apply a load to a simply supported beam (specimen). The method is generally applicable to both rigid and semi-rigid materials, but . The 3-point bending test is slightly easier to conduct and analyze. The cracking and failure in 3-point bending are well defined by one point on the specimen, under the point load. This can be easier identified than in the 4-point bending that results in the cracking of several locations between the loading noses. To improve accuracy in .

The 3-point bending test bears this name because there are three pressure points in this test setup: Two supports and a centrally loaded test punch. The specimen lies crosswise on the supports and protrudes at the sides. The 3-point bending test is the most frequently performed bending test. However, it has the disadvantage that in addition to .σ = 3 F L 2 b d 2. for a three-point bending test, where: F is the maximum load applied (N) L is the support span length (mm) b is the width of the specimen (mm) d is the depth of the specimen (mm) Flexural Modulus (Modulus of Elasticity) The flexural modulus can be .3 Point Bending Test Choose the 3pntBME315 or another bending method from the computer menus. You will indicate to the computer that you will use a new sample each time. Enter the necessary measurements prompted by the computer (i.e. width and thickness of .With a simple sample geometry, a 3-point-bend test can be used to obtain stress-strain behavior, elastic modulus in bending (flexural modulus), and failure limits in bending. The standards ASTM E855, ASTM D790 or ISO 178, and ASTM C1684 or C1161 cover the properties of flat metallic spring materials, flexural properties of plastics, and 3-point .

The flexural test on concrete can be conducted using either three point load test (ASTM C78) or center point load test (ASTM C293). The configuration of each test is shown in Figure-2 and Figure-3, respectively.The ideal 3 point bending test machine for a high velocity flexural test is an instrumented drop weight impact testing machine equipped with a 3 point bend fixture and an insert of a given shape attached to the tup. During the impact, the load is recorded by the sensor (piezoelectric or strain-gauge) embedded in the tup. .The arrangement of the testing apparatus (three-point or four-point bend, distance between supports, etc.) also influences the calculation of the beam mechanics. For more in-depth detail, click the links below to see step-by-step calculations that are made during bend tests: Example 1: Rectangular Specimen in Three Point Bending Test

ASTM E290 A-26, ISO 7438 I-8, and JIS Z2248 J-5 are some of the general standards which describe the requirements for the bend testing of metals. In a Three-Point Bend Test, a supported sample is loaded at the center point and bent to a predetermined angle or until the test sample fractures.Theory Behind 3 Point Bend Test. Three-point Bend Test procedure and working is derived from the theory of bending of the simply supported beam as explained above. To carry out the calculation of the test results after .Like the 3-point bending test, 4-point bending test and the cantilever bending test are other techniques that can be used to study the flexural stress of materials. In particular, if the material is not homogenous, ie. composites, the 4-point bending test provides a more complete study of the stress behaviour by increasing the loading region on

While it is easy to imagine why bend testing needs to be performed on rigid materials like plastics (ASTM D790) and concrete (ASTM C1609), in reality bend test applications are common in a variety .Example 1: Rectangular Three Point Bending A rectangular specimen is subjected to a three-point bending test. The specimen is 10 centimeters long, 10 millimeters wide (b) and 10 millimeters tall (h). The specimen is placed on two supports that are 5 cm apart (L), and the actuator is applying a force in the exact middle of the two supports (L/2).

three point bending test standard

three point bending test setup

Four-Point Test. A four-point bending test is very similar to a three-point test, But except the load is applied at two points simultaneously, again towards the center of the sample.It’s easiest to calculate the flexural strength when one load or force is applied one-third of the way between the supports and the second is applied two-thirds of the way between them.

The test is the same as a 3-Point bend test and is called transverse because it's perpendicular to the beam's length. Measurements include flexural strength (or bend strength, modulus of rupture,and transverse rupture strength), stiffness and yield strength. It is commonly used to evaluate polymers, metal powders, composites and wood.Wood and composites are most commonly tested with the 4-point bend test. The 4-point test requires a deflectometer to accurately measure specimen deflection at the center of the support span. Test results include flexural strength and flexural modulus. Brittle Materials. When a 3-point bend test is done on a brittle material like ceramic or .

three point bending test pdf

Learn more about ASTM D790https://www.instron.us/en-us/testing-solutions/by-test-type/flexure/the-definitive-guide-to-astm-d790?source=YTLearn more about ISO.

3 point bending test standard

Wood and composites are most commonly tested with the 4-point bend test. The 4-point test requires a deflectometer to accurately measure specimen deflection at the center of the support span. Test results include flexural strength and flexural modulus. Brittle Materials. When a 3-point bend test is done on a brittle material like ceramic or .Example 2: Cylindrical Three Point Bending A cylindrical specimen is subjected to a three-point bending test. The specimen is 10 centimeters long, has an inner radius ( ) of 2.5 mm and an outer radius ( ) of 5.0 mm. The specimen is placed on two supports that are 5 cm apart (L), and the actuator is applying a force in the exact middle of the twoEasy to install, the 3-point fixture can be modified with an optional conversion kit to provide a 4-point bending conversion. Lower anvils are adjustable to accommodate specimens of different spans. Deflection of the specimen can be measured either through crosshead displacement, or for more precise measurement you can use a mid-span direct .

3 point bending test setup

webTropic Colour's Film Title pack was a great asset for me as a beginning video editor. I was able to easily customize the templates playing with color, form, style, and placement. This helped me better understand the details of film titling and inspired me to .

3-point bending test|3 point bending test calculator